Home > Offer to Sell > Adhesives and Sealants > Adhesives and Sealants for Transportation > Electronic Potting Silicone Rubber

Electronic Potting Silicone Rubber

Inquiry

| Post Date: | Aug 11,2015 |

| Expiry Date: | Aug 10,2016 |

| Detailed Description: |

Cas No. :112926-00-8;63231-67-4

Quantity: 8000kg/dayKilograms Price:8 USD Kilograms Payment Method: T/T, Western Union,,L/C 1. Product Feature of Electronic Potting Silicone Rubber HY-9055 silicone rubber is a kind of low viscosity, Inherent flame resistance, two components addition cured potting silicone with heat-conducting. It cures with both on room temperature and heated temperature. It has the feature of the higher temperature the faster of the curing time. It can be applied to electronic components for insulation, waterproofing, fixed and flame retardant. It mainly applied in electronic components surface with materials of PC(Poly-carbonate)、PP、ABS、PVC, etc. and metal materials. 2. Typical Application of Electronic Potting Silicone Rubber HY-9055 electronic potting silicone rubber could be applied to - high powered electronics, - DC/DC module and circuit board which requires heat dissipation and high temperature resistance. -It can be broadly used for LED screen, Wind Power Generator, PCB substrate, etc. 3. Technical Guidelines of of Electronic Potting Silicone Rubber a, Pls put part A and part B in separate container and stir evenly before mixing the two part together. b, Mixing Ratio: part A: part B = 1:1 c, Deaeration the mixture in vacuum pump under 0.08 MPa for 3-5 minutes.Then the mixture could be used for pouring. Note: The thickness of the silicone affects the curing time. If the silicone used is a little thick,then the curing time will be a little longer.The temperature also affects the curing time.When in lower temperature, we suggest customers appropriately heat the mixture to accelerate vulcanization. With temperature of 80~100℃, the silicone will cure in 15 minutes; while in 25℃ room temperature, the silicone will cure around 8 hours. 4.Notes of Electronic Potting Silicone Rubber a.The following material may hinder the curing of HY-9055, So pls use after the test. When necessary, pls clean the application areas. Organotin compound or Condensation silicone with organotin Sulphur, sulfide and sulfur rubber materials. Amine compounds as well as contains the amine materials. Pewters solder flux b. HY-9055 should be sealed storage.The mixture should be used up disposably to avoid causing waste. c. HY-9055 belongs to non-dangerous goods, but keep away from mouth and eyes. d. When it gets stratified after a period of storage, Please mix it evenly before using,which does not affect the performance. |

| CAS Registry Number: | 112926-00-8;63231-67-4 |

| Synonyms: | ;Dry silica gel;cataloid;the(r) desiccant;silicon dioxide pyrogene, high dispers;silver nitrate-impregnated silica gel;sulfuric acid-impregnated silica gel;sand;dry silica gel,high-effecienty;amorphous silica gel;gel & precipitated silica;silica, amorphous;silica, amorphous, precipitated and gel;silica gel desiccant;silicon dioxide, amorphous gel;amorphous silicadust;amorphous silicon dioxide;prep sep si;silicic acid, precipitated;colloidal silica;Silicon dioxide, amorphous gel in isopropanol;Silicasol;silica sol;silica solution; |

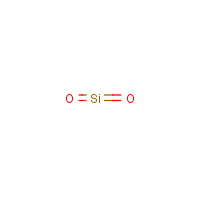

| Molecular Formula: | SiO2 |

| Molecular Weight: | 60.0843 |

| Molecular Structure: |

|

| Hazard Symbols: |  Xi:刺激性物质‖T; Xi:刺激性物质‖T; |

| Risk Codes: | R20:吸入有害‖R37; |

| Safety Description: | S22:不要吸入粉尘‖S45 ; |

| Company: | Shenzhen Hong Ye Jie Technology .Co .Ltd [ China ] |

| Contact: | Angela |

| Tel: | +86-075-89311987 |

| Fax: | |

| Email: | hyh@resinpu.com |

-

Disclaimer statement:The information and data included above have been realized by the enterprises and compiled by the staff, and are subject to change without notice to you. The Chemnet makes no warranties or representations whatsoever regarding the facticity, accuracy and validity of such information and data. In order to ensure your interest, we suggest you chose the products posted by our gold suppliers or VIP members.